NBR is mainly produced by low-temperature emulsion polymerization method, with excellent oil resistance, high abrasion resistance, good heat resistance and strong adhesion. Its disadvantages are poor low temperature resistance, poor ozone resistance, poor insulation performance, and slightly lower elasticity. NBR is mainly used in the manufacture of oil-resistant rubber products, a variety of oil-resistant gaskets, gaskets, sleeves, soft packaging, soft hose, printing and dyeing rollers, cable rubber materials, etc. It has become an essential elastic material in the automotive, aviation, petroleum, copying and other industries.

NBR is mainly produced by low temperature emulsion polymerization method, with excellent oil resistance, high wear resistance, good heat resistance and strong adhesion. Its disadvantages are poor low temperature resistance, poor ozone resistance, poor insulation performance, and slightly lower elasticity. NBR is mainly used in the manufacture of oil-resistant rubber products, a variety of oil-resistant gaskets, gaskets, sleeves, soft packaging, soft rubber tubes, printing and dyeing rollers, cable rubber materials, etc. It has become an essential elastic material in the automotive, aviation, petroleum, copying and other industries.

NBR has excellent oil resistance. Butadiene monomer can be copolymerized into three different chain structures: cis, trans and 1,2-焼 groups. The typical NBR structure is about 78% trans. Due to the presence of cyano in the NBR molecular chain structure, the oil resistance (e.g., to mineral oil, liquid fuels, animal and vegetable oils, and solvents) is better than that of natural rubber, neoprene, and styrene-butadiene rubber. Compared with other rubbers, NBR has a wider range of service temperature, its long-term service temperature is 120oC. Meanwhile, NBR has good low temperature resistance, the lowest glass transition temperature can reach -55oC.

NBR has good chemical stability and good processing performance. As its relative density increases with the content of propylene nitrile in its structure, the vulcanization speed is accelerated and the tensile strength performance is improved, but the resilience performance decreases and the cold resistance becomes poor. NBR is a semiconductor rubber because the cyano in NBR is easily polarized by electric field, thus the dielectric property decreases. nBR can be divided into 5 categories of ultra-high, high, medium-high, medium and low propylene nitrile according to the level of ACN content. The production method is divided into continuous and intermittent polymerization method. Continuous polymerization method is usually used for few varieties and large production volume production with low consumption. Intermittent polymerization method is suitable for multi-variety and small batch production, polymerization sign using a small number of high consumption of engineering and construction. So far, it does not see the trend of mutual replacement.

Although NBR has excellent physical and mechanical properties and processing performance, but long-term in the acidic gasoline and high temperature (150oC) environment is not as good as the performance of fluorine-like rubber and propionic acid cool rubber, for this reason German companies, Canadian companies and Japanese companies to develop excellent performance of hydrogenated nitrile rubber (HNBR). In addition, we have also developed NBR with extremely high cold resistance and high purity and XNBR.

Translated with www.DeepL.com/Translator (free version)

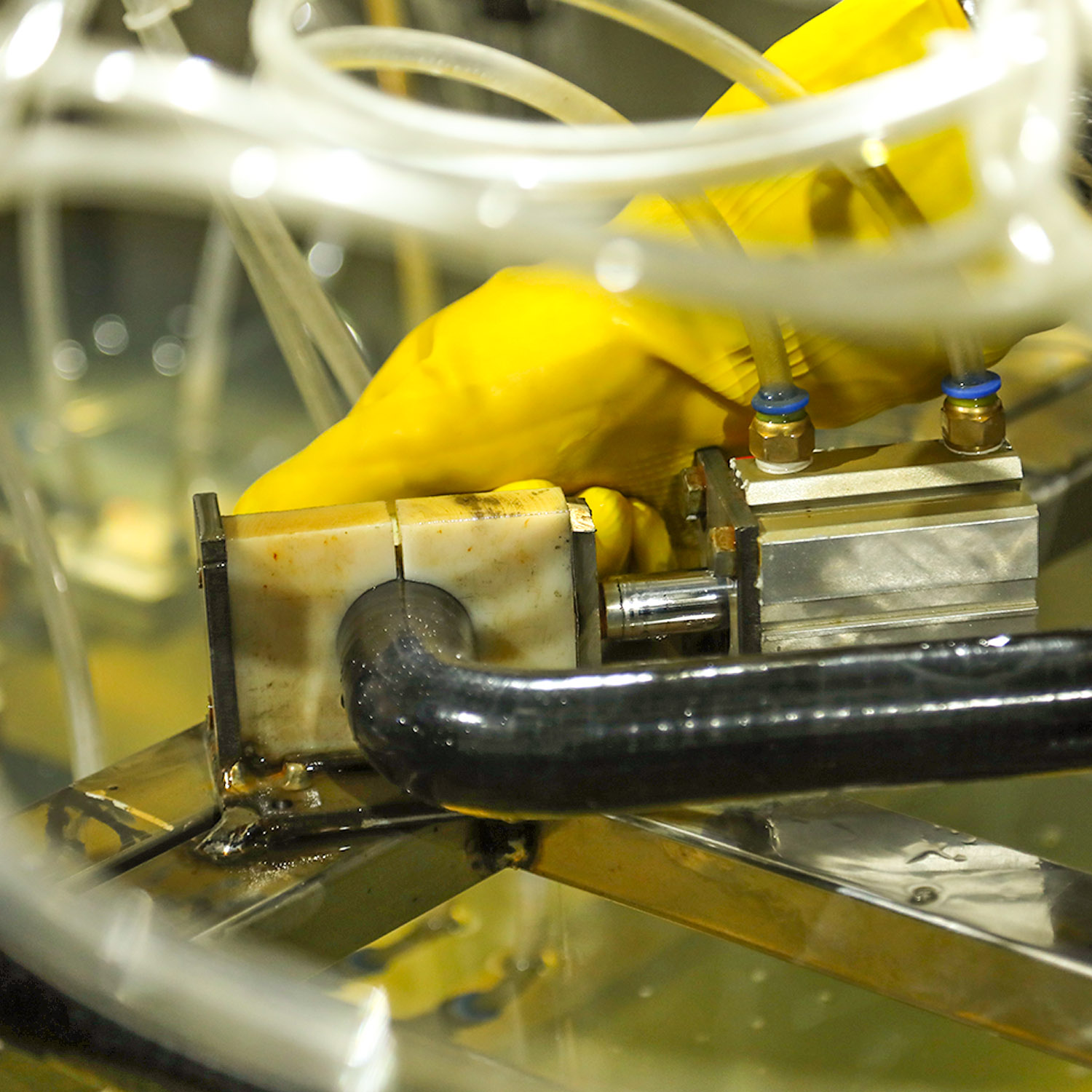

Hebei CONQI VEHICLE FITTINGS Co., Ltd. is a company dedicated to produce and distribute of auto rubber hose, EPDM hose, food grade hose and pvc hose etc with rich production experience, advanced production technology and a complete and scientific quality management system. In 2009, the company completed a total industrial output value of 10.01 million yuan and completed a warehouse tax of 250, 000 yuan. All of them are matched with more than 30 domestic OEMs such as Jinlong, Yutong, Ankai, and Zhongtong, and with international branches of Volvo and India, New Zealand, Thailand, Taiwan, Poland, Israel, Britain, Egypt, Spain, Turkey, Brazil, Singapore, Germany and more than 20 countries and regions have obtained supporting facilities. Adhering to the tenet of “continuous improvement , excellence, excellent quality, and customer satisfaction”, we keenly capture the latest international technology and product information, constantly design and develop new products, and provide customers .

Post time: Dec-05-2022