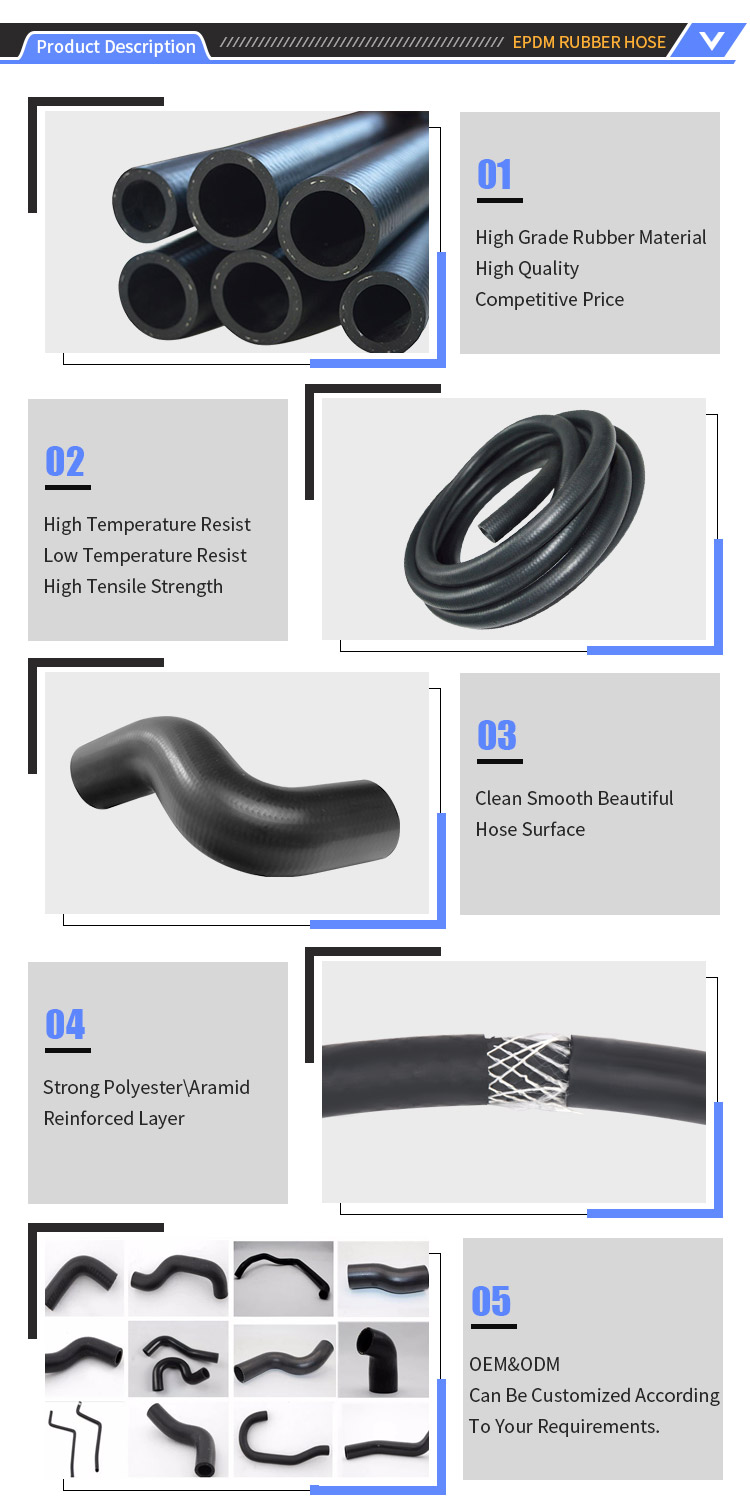

Custom Manufacture Wholesale Epdm Radiator Rubber Flexible 4-Layers Hose For Brake Fluid

How does the silicone hose made

Silicone tubes have great applications in life. The most common applications include medical silicone tubes, baby bottle nipple silicone tubes, corrosion-resistant silicone tubes, water dispenser silicone tubes, etc. It can be seen that silicone tubes are indispensable in life. , So, having said so many applications of silicone tube, do you know what are the production process of silicone tube? Do you know the specific process knowledge? Let me know about it with me~

Extrusion production process of silicone hose:

1. Rubber mixing: The raw materials of the rubber compound are mixed in the twin-cylinder rubber mixing machine with double 24 or platinum vulcanizing agent or silica gel masterbatch, and then pressed into a layer of silicone extrusion material with uniform thickness.

2. Extrusion molding: install the mold on the head of the silicone extruder. Divide the refined rubber into shapes of the same size and length so that it is convenient to feed the material from the inlet of the extruder. Then feed the material through a silicone extruder, extrude the molded but very soft silicone hose, put the silicone hose into an 8-meter-long drying tunnel, and vulcanize at high temperature. The silicone hose that comes out through the drying tunnel can be a semi-finished product, and then wrap it.

3. High-temperature vulcanization: Put the wound silicone hose in the oven, normal silicone 180 degrees, gas-phase silicone hose 200 degrees, high temperature for 2 hours, perform secondary vulcanization to remove the odor on the silicone hose, prevent blooming and change Yellow.

4. Perform follow-up processing: the rest is to perform follow-up processing such as cutting or bonding according to the length required by the customer. Then package and ship to customers as required.